Maximizing Output: The Benefits of Using Folder Gluers in Manufacturing

Maximizing Output: The Benefits of Using Folder Gluers in Manufacturing

Table of Contents

- 1. Introduction to Folder Gluers

- 2. What is a Folder Gluer?

- 3. How Folder Gluers Work

- 4. Benefits of Using Folder Gluers in Manufacturing

- 5. Applications of Folder Gluers in Various Industries

- 6. Choosing the Right Folder Gluer for Your Manufacturing Needs

- 7. Maintenance and Care of Folder Gluers

- 8. The Future of Folder Gluers in Manufacturing

- 9. FAQs

- 10. Conclusion

1. Introduction to Folder Gluers

In the fast-paced world of manufacturing, maximizing output while maintaining quality is paramount. As industries continue to evolve, the need for efficient solutions has led to the increased use of **folder gluers**. These machines play a critical role in the production of various packaging materials, streamlining processes that were once labor-intensive and time-consuming. In this article, we will delve deep into the multifaceted benefits of using folder gluers in manufacturing, showcasing how they can significantly enhance productivity and reduce operational costs.

2. What is a Folder Gluer?

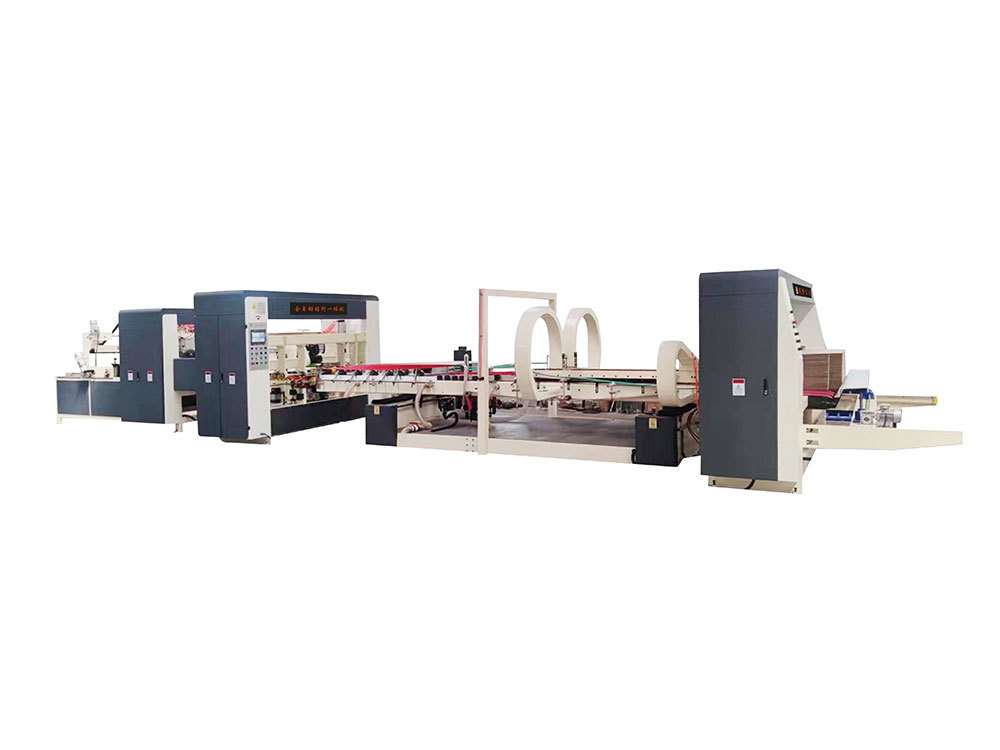

A **folder gluer** is a specialized machine designed to fold and glue materials, primarily used in packaging and printing industries. This equipment is essential for creating boxes, cartons, and other packaging products with precision and speed. The folder gluer functions by taking flat sheets of paperboard or corrugated material, folding them into the desired shape, and applying adhesive at specific points to secure the structure.

3. How Folder Gluers Work

Folder gluers operate using a combination of mechanical and pneumatic systems. The process typically involves the following steps:

1. **Material Feeding:** Flat sheets of material are fed into the machine, either manually or automatically.

2. **Folding Mechanism:** The machine features various folding plates that guide the material through a series of folds, shaping it into boxes or cartons.

3. **Gluing Process:** As the material is folded, adhesive is applied at designated points using either hot melt glue or cold glue systems, ensuring that the final product is securely bonded.

4. **Output Conveyor:** Finally, the finished product is discharged onto a conveyor belt, ready for packaging or further processing.

The speed of these machines can reach impressive levels, allowing manufacturers to produce hundreds or even thousands of units per hour.

4. Benefits of Using Folder Gluers in Manufacturing

The advantages of integrating folder gluers into manufacturing processes are numerous. Here, we highlight the key benefits:

4.1 Efficiency and Speed

One of the most significant benefits of folder gluers is their ability to dramatically increase production speed. Traditional methods of folding and gluing often require extensive manual labor, which can be time-consuming and prone to errors. In contrast, folder gluers automate these processes, allowing for rapid production cycles. This efficiency not only saves time but also enables manufacturers to meet large orders and tight deadlines with ease.

4.2 Cost-Effectiveness

Investing in a folder gluer can lead to long-term cost savings. By reducing labor costs associated with manual folding and gluing, companies can allocate their workforce to other critical areas. Additionally, folder gluers minimize material waste through precise cutting and gluing techniques, further enhancing cost efficiency. Over time, the return on investment (ROI) from using these machines can be substantial.

4.3 Quality and Precision

Quality is a non-negotiable aspect of manufacturing, especially in packaging where durability and aesthetics matter. Folder gluers are engineered for high precision, ensuring that each fold and glue application is consistent. This level of accuracy results in uniform products that meet industry standards, leading to higher customer satisfaction and reduced returns.

4.4 Versatility

Folder gluers are incredibly versatile, making them suitable for a wide range of applications. They can handle different materials, including paperboard, corrugated board, and plastic, allowing manufacturers to diversify their product offerings. Furthermore, many folder gluers can be easily adjusted for various sizes and shapes, accommodating specific customer requirements without the need for extensive retooling.

5. Applications of Folder Gluers in Various Industries

The applications of folder gluers are vast and span several industries:

- **Packaging Industry:** Folder gluers are widely used to create boxes, cartons, and displays, ensuring efficient and reliable packaging solutions.

- **Printing Industry:** In printing, they help produce brochures, flyers, and booklets, facilitating a streamlined finishing process.

- **Food Industry:** The food sector utilizes folder gluers for creating secure and visually appealing packaging for products ranging from snacks to beverages.

- **Pharmaceutical Industry:** In pharmaceuticals, folder gluers are essential for packaging medicine boxes, ensuring compliance with safety regulations.

- **E-commerce and Retail:** As online shopping continues to grow, folder gluers play a critical role in producing packaging that is both practical and attractive for shipping purposes.

6. Choosing the Right Folder Gluer for Your Manufacturing Needs

Selecting the appropriate folder gluer involves several considerations:

- **Production Volume:** Evaluate your production needs. High-volume operations may require advanced models with faster speeds and greater automation.

- **Material Compatibility:** Ensure the folder gluer can handle the materials you intend to use, whether paperboard, corrugated cardboard, or other materials.

- **Size and Configuration:** Consider the sizes of the products you will produce. Some folder gluers are designed for specific sizes, while others offer adjustable settings.

- **Budget:** Determine your budget and find a balance between cost and features. It's crucial to invest in quality machinery that meets your long-term needs without exceeding your budget.

- **Manufacturer Support:** Look for reputable manufacturers that provide excellent customer support, including installation, training, and maintenance services.

7. Maintenance and Care of Folder Gluers

Proper maintenance of folder gluers is essential to ensure longevity and optimal performance. Here are some key maintenance tips:

- **Regular Cleaning:** Keep the machine clean by regularly removing glue residues and debris that could affect functionality.

- **Lubrication:** Ensure all moving parts are properly lubricated to prevent wear and tear.

- **Calibration Checks:** Periodically check and calibrate the machine to maintain precision and performance levels.

- **Professional Servicing:** Schedule routine inspections with a qualified technician to address any potential issues before they escalate.

8. The Future of Folder Gluers in Manufacturing

As technology continues to advance, the future of folder gluers looks promising. Innovations in automation, such as the integration of artificial intelligence and robotics, are expected to enhance the capabilities of these machines. Additionally, developments in adhesive technology could lead to more efficient gluing processes and improved product integrity. Manufacturers that adopt these innovations will likely gain a competitive edge in the marketplace.

9. FAQs

What is the average speed of a folder gluer?

The average speed of a folder gluer can range from 100 to 1,200 sheets per hour, depending on the model and complexity of the job.

Can folder gluers handle different types of materials?

Yes, folder gluers can handle a variety of materials, including paperboard, corrugated cardboard, and certain plastics.

How much does a folder gluer cost?

The cost of a folder gluer varies widely based on features and capabilities, ranging from a few thousand to several hundred thousand dollars.

Are folder gluers difficult to operate?

While folder gluers may require some training, many modern machines are designed for user-friendly operation, often featuring intuitive controls and automated settings.

What maintenance is required for a folder gluer?

Regular cleaning, lubrication, and periodic calibration are essential maintenance tasks to keep a folder gluer operating efficiently.

10. Conclusion

Incorporating folder gluers into manufacturing processes offers numerous advantages, from increased efficiency and cost savings to enhanced quality and versatility. As industries evolve and demand for high-quality packaging solutions grows, these machines will continue to play a pivotal role in maximizing output. By understanding the benefits and applications of folder gluers, manufacturers can make informed decisions that drive success and growth in a competitive landscape. Investing in this technology not only streamlines production but also positions companies for long-term sustainability and profitability in the ever-changing world of manufacturing.

TAG:

Related Posts

Maximizing Efficiency: The Essential Benefits of Upgrading Your Die Cutting Machine Technology

The Benefits of Upgrading Your Die Cutting Machine Technology

In the dynamic world of manufacturing and printing, staying ahead of the competition requires more than just traditional methods. Upgrading your die cutting machine technology can significantly impact your operations. This article explores the myriad benefits of modernizing your die cutting machines, highlighting the advantages in effic