Exploring the Versatility of Flute Laminator Machines in Paper Processing

Exploring the Versatility of Flute Laminator Machines in Paper Processing

Introduction to Flute Laminator Machines

Flute laminator machines play a pivotal role in the paper processing industry. These machines are designed to laminate and enhance the durability and quality of paper products through a specialized process that involves layering materials. As the demand for high-quality packaging and paper products increases, understanding the versatility of flute laminator machines becomes crucial for manufacturers and businesses alike. In this article, we will explore the various features, benefits, and applications of these machines, highlighting their significance in modern paper processing.

What is a Flute Laminator Machine?

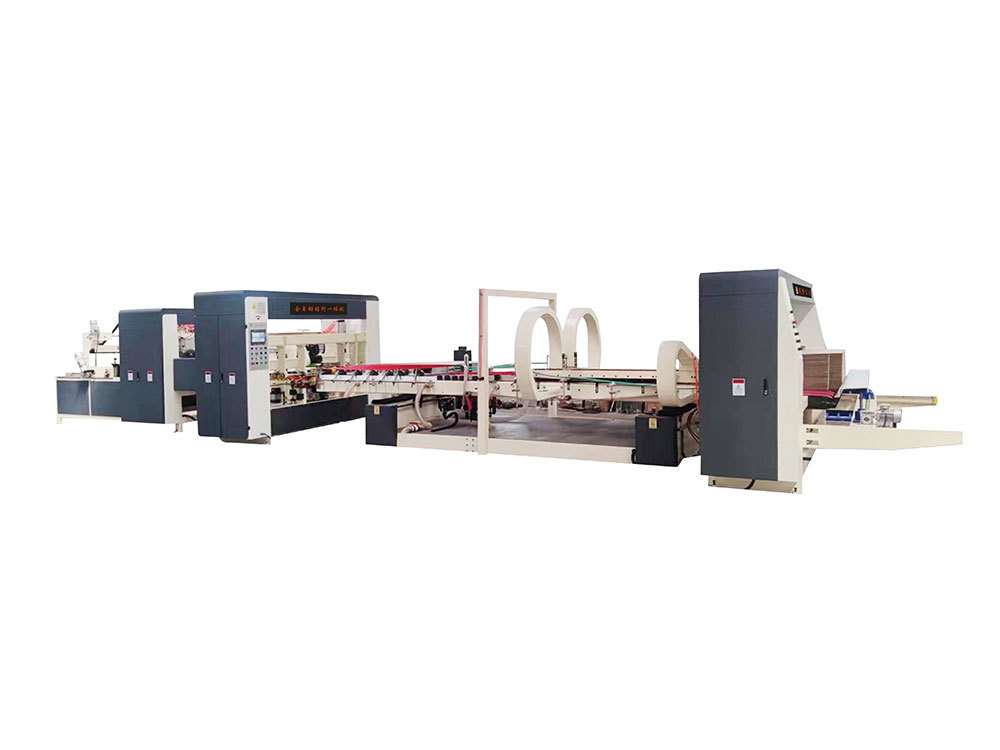

A flute laminator machine is an advanced piece of equipment utilized for the lamination of paper sheets, typically using a layer of adhesive, plastic, or other materials. The unique design often includes a flute or wavy structure, which enhances the bonding process and provides added strength to the laminated materials. These machines are versatile and can handle various substrate materials, making them suitable for different applications within the paper industry.

The Mechanics of Flute Laminator Machines

Flute laminator machines typically operate using a series of rollers and heated plates that press and bond the layers of paper and laminate together. Understanding the mechanics involved is crucial for optimizing their use in production lines. Here’s a breakdown of the core components:

1. Feeding System

The feeding system ensures a smooth transition of paper sheets into the laminator. It often includes a series of belts or rollers that help align and guide the sheets for precise processing.

2. Pre-Heating Units

Before the lamination process begins, the paper and laminate materials are pre-heated to ensure better adhesion. This step is vital for improving the overall quality of the finished product.

3. Laminating Rollers

The heart of the flute laminator, these rollers apply pressure and heat to the layers, ensuring a strong bond. They can be adjusted to accommodate different thicknesses and types of materials.

4. Cooling Section

After lamination, the sheets must be cooled to solidify the adhesive and maintain the integrity of the laminate. This section typically uses air or water cooling systems to bring down the temperature quickly.

Benefits of Using Flute Laminator Machines in Paper Processing

Investing in flute laminator machines can offer numerous advantages for businesses involved in paper processing. Here are key benefits that highlight their importance:

1. Enhanced Durability

Flute laminator machines increase the strength and durability of paper products, making them resistant to wear and tear. This is particularly important for packaging materials that need to withstand transportation and handling.

2. Improved Aesthetic Appeal

Laminated paper products often have a glossy or matte finish, enhancing their visual appeal. This is essential in markets where presentation is key, such as in advertising and promotional materials.

3. Versatility

These machines can handle various substrates, including cardboard, paper, and plastics. Their adaptability allows businesses to produce a wide range of products, from packaging boxes to high-quality brochures.

4. Cost Efficiency

By streamlining the lamination process, flute laminator machines can significantly reduce labor costs and production time. This efficiency translates into higher output rates and better profit margins.

5. Eco-Friendly Options

Many modern flute laminator machines are designed to work with eco-friendly laminating materials, aligning with the growing demand for sustainable practices in the paper industry.

Applications of Flute Laminator Machines

Flute laminator machines find application across various sectors within the paper industry. Here are some prominent uses:

1. Packaging Industry

In the packaging industry, flute laminator machines are essential for creating strong, durable packaging solutions. They are commonly used to laminate corrugated cardboard boxes, ensuring they can withstand heavy loads without compromising their structural integrity.

2. Advertising and Marketing Materials

High-quality brochures, flyers, and promotional materials often require lamination to enhance their appearance and longevity. Flute laminator machines enable businesses to produce visually appealing marketing materials that capture consumer interest.

3. Stationery Products

From notebooks to planners, laminated covers provide durability and a premium feel to stationery products. Manufacturers leverage flute laminator machines to produce a variety of stationery items that stand out in the market.

4. Educational Materials

Educational institutions often utilize laminated materials for durability. Textbooks, educational charts, and flashcards benefit from lamination, ensuring they last longer and withstand frequent handling.

5. Custom Products

Many businesses require customized laminated products. Flute laminator machines are versatile enough to accommodate unique requests, allowing companies to create bespoke items tailored to their clients' needs.

Types of Flute Laminator Machines

Understanding the different types of flute laminator machines can help businesses choose the right equipment for their production needs.

1. Automatic Flute Laminator Machines

These machines are designed for high-volume production. Equipped with advanced technology, automatic flute laminators streamline the lamination process, reducing manual intervention and minimizing errors.

2. Semi-Automatic Flute Laminator Machines

Offering a balance between manual and automatic operations, semi-automatic machines are suitable for businesses looking to increase efficiency without a significant investment. They require some manual setup but automate key processes.

3. Manual Flute Laminator Machines

These machines are ideal for small-scale operations or businesses just starting in the paper processing industry. Manual machines offer flexibility and are often more affordable, although they require more labor input.

Key Features to Consider When Choosing a Flute Laminator Machine

When sourcing a flute laminator machine, several features should be taken into account to ensure optimal performance and productivity.

1. Production Capacity

Evaluate the machine's capacity to meet your production demands. Higher capacity machines may be necessary for larger operations, while smaller businesses may find lower-capacity models sufficient.

2. Versatility

Consider whether the machine can handle various substrates. A versatile machine can adapt to different material types, allowing for greater flexibility in production.

3. Energy Efficiency

Investing in energy-efficient models can lead to significant cost savings over time. Look for machines that utilize modern technology to reduce energy consumption.

4. Ease of Use

User-friendly machines simplify the training process for operators. Consider machines with intuitive controls and clear instructions to minimize downtime.

5. Maintenance Requirements

Regular maintenance is essential for optimal machine performance. Assess the maintenance needs of the laminator and choose options that are easy to service.

Best Practices for Operating Flute Laminator Machines

Maximizing the efficiency of flute laminator machines requires adherence to best practices during operation.

1. Regular Training for Operators

Ensure that all operators receive proper training on the equipment. Regular training sessions can help maintain high safety standards and reduce the likelihood of errors.

2. Routine Maintenance Checks

Establish a regular maintenance schedule to keep the machine in optimal condition. Routine checks for wear and tear can prevent costly breakdowns and extend the machine's lifespan.

3. Quality Control Measures

Implement quality control measures at various stages of production. Regular inspections can help identify any issues early on, ensuring that only high-quality products reach the market.

4. Optimize Production Settings

Adjust the machine settings based on the specific materials being processed. Optimizing speed, pressure, and temperature can lead to better results and reduce waste.

5. Stay Updated with Technology

The paper processing industry is continually evolving. Staying informed about the latest advancements in laminating technology can help businesses remain competitive.

Frequently Asked Questions (FAQs)

1. What materials can be laminated using flute laminator machines?

Flute laminator machines can laminate various materials, including paper, cardboard, and plastic substrates, making them versatile for different applications.

2. How do I maintain a flute laminator machine?

Regular maintenance involves checking for wear and tear, cleaning components, and ensuring that all settings are correctly adjusted for optimal performance.

3. Can flute laminator machines handle custom orders?

Yes, many flute laminator machines are designed to accommodate custom orders, allowing businesses to create tailored products according to specific client needs.

4. What are the differences between automatic and manual flute laminator machines?

Automatic machines streamline the lamination process and require less manual input, while manual machines require more labor but can be more affordable for small-scale operations.

5. Are there eco-friendly laminating options available?

Yes, many modern flute laminator machines can work with eco-friendly laminating materials, catering to the growing demand for sustainable practices in the paper industry.

Conclusion

The versatility of flute laminator machines in the paper processing industry is undeniable. From enhancing the durability of packaging solutions to improving the aesthetic appeal of marketing materials, these machines are integral to producing high-quality paper products. By understanding their functionality, applications, and benefits, businesses can make informed decisions to optimize their production processes and meet the evolving demands of the market. Investing in the right flute laminator machine not only boosts efficiency but also positions businesses for success in a competitive landscape.

TAG:

Related Posts

Understanding Die Cutting Machines: A Key Element in Post-Processing Manufacturing

Die cutting machines play a pivotal role in the manufacturing sector, particularly within post-processing operations. These machines are designed to cut various materials into specific shapes and sizes, making them indispensable for industries such as packaging, textiles, and crafting. Understanding the intricacies of die cutting machines can help professionals optimize their workflows and enhance