Understanding the Flexographic Printing Press: A Comprehensive Guide

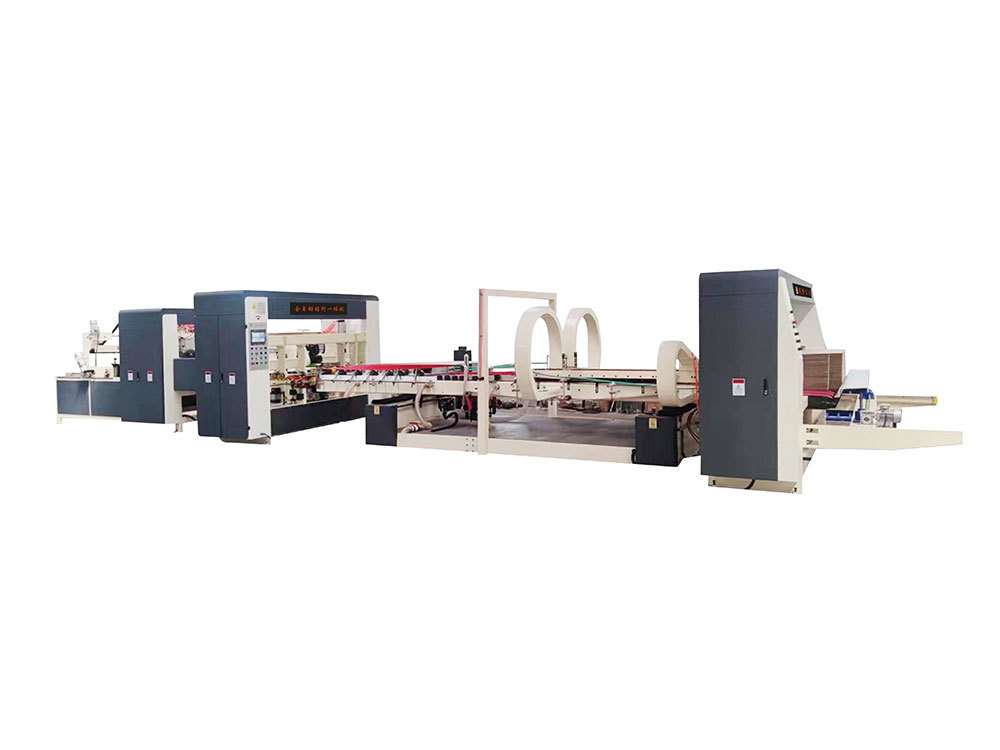

Flexographic printing press, also known simply as flexo press, is a modern printing technology that has transformed the landscape of packaging and label printing. It employs a rotary printing process that uses flexible relief plates, which allows for rapid printing on a variety of substrates, including plastic, paper, and metal foils. This versatility makes it a popular choice across various industries, particularly in the packaging sector.

One of the primary advantages of flexographic printing is its ability to produce high-quality prints at high speeds. The technology is designed to handle long runs efficiently, which can significantly reduce production time and costs. This is particularly beneficial for manufacturers who require consistent print quality over large volumes, such as in the production of labels, packaging materials, and corrugated boxes.

Another notable feature of flexographic printing presses is their adaptability to different inks. Flexo presses can use a wide range of ink types, including water-based, solvent-based, and UV inks. This flexibility allows for a broader spectrum of applications, enabling manufacturers to choose inks that best suit their specific needs, whether it be eco-friendliness, drying speed, or color vibrancy.

The setup and maintenance of a flexographic printing press can also be streamlined, making it user-friendly for operators. Advanced technology and automation are often integrated into modern flexo presses, which can improve accuracy and reduce waste during the printing process. This technological evolution ensures that production lines remain efficient and cost-effective.

Furthermore, the environmental impact of printing is a growing concern among manufacturers. Flexographic printing presses are often considered more sustainable than other printing methods due to their ability to use eco-friendly inks and their efficient use of resources. By implementing flexographic technology, companies can reduce their carbon footprint and contribute to more sustainable manufacturing practices.

In conclusion, understanding the capabilities and benefits of a flexographic printing press is essential for anyone involved in manufacturing and processing machinery. Its versatility, efficiency, and adaptability make it a valuable asset in the production line, capable of meeting the diverse needs of the packaging and printing industries. By leveraging the advantages of flexographic printing, manufacturers can not only enhance their product offerings but also align with modern sustainability initiatives.

One of the primary advantages of flexographic printing is its ability to produce high-quality prints at high speeds. The technology is designed to handle long runs efficiently, which can significantly reduce production time and costs. This is particularly beneficial for manufacturers who require consistent print quality over large volumes, such as in the production of labels, packaging materials, and corrugated boxes.

Another notable feature of flexographic printing presses is their adaptability to different inks. Flexo presses can use a wide range of ink types, including water-based, solvent-based, and UV inks. This flexibility allows for a broader spectrum of applications, enabling manufacturers to choose inks that best suit their specific needs, whether it be eco-friendliness, drying speed, or color vibrancy.

The setup and maintenance of a flexographic printing press can also be streamlined, making it user-friendly for operators. Advanced technology and automation are often integrated into modern flexo presses, which can improve accuracy and reduce waste during the printing process. This technological evolution ensures that production lines remain efficient and cost-effective.

Furthermore, the environmental impact of printing is a growing concern among manufacturers. Flexographic printing presses are often considered more sustainable than other printing methods due to their ability to use eco-friendly inks and their efficient use of resources. By implementing flexographic technology, companies can reduce their carbon footprint and contribute to more sustainable manufacturing practices.

In conclusion, understanding the capabilities and benefits of a flexographic printing press is essential for anyone involved in manufacturing and processing machinery. Its versatility, efficiency, and adaptability make it a valuable asset in the production line, capable of meeting the diverse needs of the packaging and printing industries. By leveraging the advantages of flexographic printing, manufacturers can not only enhance their product offerings but also align with modern sustainability initiatives.

TAG:

Related Posts

Understanding Die Cutting Machines: A Key Element in Post-Processing Manufacturing

Die cutting machines play a pivotal role in the manufacturing sector, particularly within post-processing operations. These machines are designed to cut various materials into specific shapes and sizes, making them indispensable for industries such as packaging, textiles, and crafting. Understanding the intricacies of die cutting machines can help professionals optimize their workflows and enhance