Understanding Die Cutting Machines: A Comprehensive Guide for Manufacturers

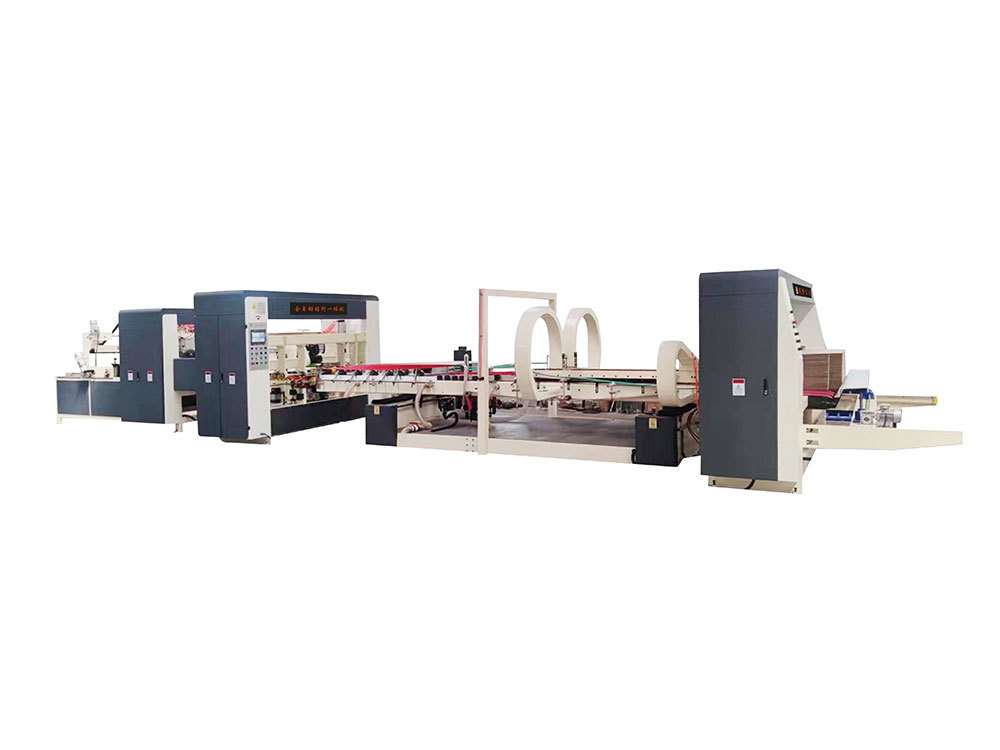

Die cutting machines are vital tools in the manufacturing and post-processing industries, particularly for businesses involved in the production of labels, packaging, and various automotive and industrial components. These machines utilize a sharp die to cut materials into specific shapes and sizes, offering precision and efficiency that manual cutting methods cannot match.

One of the primary functions of a die cutting machine is to streamline the production process. By enabling high volumes of consistent cuts, these machines dramatically reduce material waste and labor costs. The ability to produce intricate designs and shapes is especially beneficial for industries that demand customization and flexibility in their products.

Die cutting machines come in various types, including flatbed, rotary, and digital models, each catering to specific needs and materials. Flatbed die cutters are ideal for thicker substrates, while rotary die cutters excel in high-speed applications. Digital die cutting machines, on the other hand, are perfect for short runs and prototyping, allowing manufacturers to test designs without incurring significant costs.

Moreover, the versatility of die cutting machines allows them to work with a wide range of materials, including paper, cardboard, plastic, and even textiles. This flexibility makes them suitable for diverse industries, including packaging, automotive, and textiles. Whether you're crafting delicate paper products or robust industrial components, there's a die cutting solution available for your needs.

In addition to efficiency and versatility, die cutting machines enhance product quality. With precision cutting capabilities, manufacturers can achieve clean edges and intricate designs, significantly improving the overall aesthetic appeal of products. This level of detail is crucial for businesses aiming to maintain a competitive edge in their respective markets.

The integration of die cutting machines into production lines can also lead to increased automation. Many modern die cutting machines can be easily connected with other automated systems, further enhancing workflow efficiency. This automation minimizes human error and maximizes output, allowing manufacturers to focus on scaling their operations while ensuring quality control.

In conclusion, investing in a die cutting machine can significantly enhance the efficiency and quality of your manufacturing processes. By understanding the various types of die cutting machines and their applications, manufacturers can make informed decisions that align with their operational needs and product goals. Ultimately, the right die cutting solution can pave the way for innovation and growth in your business.

One of the primary functions of a die cutting machine is to streamline the production process. By enabling high volumes of consistent cuts, these machines dramatically reduce material waste and labor costs. The ability to produce intricate designs and shapes is especially beneficial for industries that demand customization and flexibility in their products.

Die cutting machines come in various types, including flatbed, rotary, and digital models, each catering to specific needs and materials. Flatbed die cutters are ideal for thicker substrates, while rotary die cutters excel in high-speed applications. Digital die cutting machines, on the other hand, are perfect for short runs and prototyping, allowing manufacturers to test designs without incurring significant costs.

Moreover, the versatility of die cutting machines allows them to work with a wide range of materials, including paper, cardboard, plastic, and even textiles. This flexibility makes them suitable for diverse industries, including packaging, automotive, and textiles. Whether you're crafting delicate paper products or robust industrial components, there's a die cutting solution available for your needs.

In addition to efficiency and versatility, die cutting machines enhance product quality. With precision cutting capabilities, manufacturers can achieve clean edges and intricate designs, significantly improving the overall aesthetic appeal of products. This level of detail is crucial for businesses aiming to maintain a competitive edge in their respective markets.

The integration of die cutting machines into production lines can also lead to increased automation. Many modern die cutting machines can be easily connected with other automated systems, further enhancing workflow efficiency. This automation minimizes human error and maximizes output, allowing manufacturers to focus on scaling their operations while ensuring quality control.

In conclusion, investing in a die cutting machine can significantly enhance the efficiency and quality of your manufacturing processes. By understanding the various types of die cutting machines and their applications, manufacturers can make informed decisions that align with their operational needs and product goals. Ultimately, the right die cutting solution can pave the way for innovation and growth in your business.

TAG:

Related Posts

Understanding Die Cutting Machines: A Key Element in Post-Processing Manufacturing

Die cutting machines play a pivotal role in the manufacturing sector, particularly within post-processing operations. These machines are designed to cut various materials into specific shapes and sizes, making them indispensable for industries such as packaging, textiles, and crafting. Understanding the intricacies of die cutting machines can help professionals optimize their workflows and enhance