Application and characteristics

◆ Advanced leading edge paper feeding system, simple operation, high precision.

◆ The position of the left and right baffle is electrically adjusted by the screw, and the right baffle is attached with a pneumatic patting device.

◆ Install 7-inch true color touch screen, you can preset 200 groups of orders, order query, zero, order input, the whole machine synchronous zero, phase automatic/manual adjustment, machine parameter management, lift plate ink manualautomatic control, automatic display of production quantity and production speed and set production quantity.

◆ Adopt electric control to adjust the axial, longitudinal and box height dimensions of each cutter holder.

◆ The slotting phase adopts PLC touch screen control and electric digital 360° adjustment loperation, stop can be adjusted). Phase zero device.

◆ Single shaft double knife slotting, box height adjustment using internal gear electric adjustment structure, so that lubricating oil is not easy to pollute the carton. And the box height adjustment has anti- collision protection device, will not damage the machine.

Technological parameter

| Type | ZYKM-1022 | ZYKM-1224 | ZYKM-1228 | ZYKM-1424 | ZYKM-1428 | ZYKM-1624 | ZYKM-1628 | ZYKM-1632 | |

| Max. speed(piece/min) | 200 | 200 | 190 | 200 | 190 | 170 | 170 | 150 | |

| Paper feeding precision(mm ) | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | |

| Max. feed size(mm) | 1000×2300 | 1200×2500 | 1200×2900 | 1400×2500 | 1400×2900 | 1600×2500 | 1600×2900 | 1600×3300 | |

| Min. feed size(mm) | 300×600 | 350×600 | 350×600 | 400×600 | 400×600 | 450×600 | 450×600 | 450×600 | |

| Size of drawing paper(mm) | 1300×2100 | 1500×2500 | 1500×2900 | 1700×2500 | 1700×2900 | 2000×2500 | 2000×2900 | 2000×3300 | |

| Max. printing area(mm) | 1000×2200 | 1200×2400 | 1200×2800 | 1400×2400 | 1400×2800 | 1600×2400 | 1600×2800 | 1600×3200 | |

| Printing set(mm) | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | |

| Thickness of standard printing plate (mm) | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | |

| Min. slotting interval (mm) | Positive knife | 160×160 | 160×160 | 160×160 | 160×160 | 160×160 | 160×160 | 160×160 | 180×180 |

| Scalpel | 270×65 | 270×65 | 270×65 | 270×65 | 270×65 | 270×65 | 270×65 | 290×70 | |

| Max. groove depth(mm) | 250 | 300 | 300 | 350 | 350 | 400 | 400 | 400 | |

| Slotting accuracy (mm) | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | |

| Die cutting precision (mm) | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | |

Paper feed unit

◆ Roller type front feed system, independent electronic shaft, extended feed. Adopting international advanced technology, the system is stable and the paper feeding precision is high.

◆ The adsorption fan assists the paper feeding, and the air volume is adjusted by frequency conversion to ensure the smooth feeding of the curved cardboard.

◆ Suitable for manual adjustment of 3, 5, 7 layers of corrugated cardboard front baffle, dial display, direct and convenient. The left and right side baffles are adjusted separately and displayed digitally.

◆ Tailgate electric adjustment, simple and convenient.

◆ Double conveyor roller mechanism, the first group of paper feed wheel adopts floating structure, the pressure can be adjusted by spring force. The gap is adjusted manually, and the sign shows the adjustment range 1-12mm.

◆ Feed roller entrance brush, used to remove impurities on the surface of the cardboard. There is a dust mechanism between the two paper feeding wheels, which is used to absorb impurities on the surface of the cardboard to improve the printing quality.

Printing unit

◆ Printing roller: steel cylinder, surface grinding, hard chrome plated. Dynamic balance correction, smooth link.

◆ The axial adjustment adopts manual adjustment, and the axial adjustment range is 10mm.

◆ Ratchet fixed reel shaft. Full plate hanging plate groove loading and unloading printing plate, foot switch electric control positive and negative rotation.

◆ The pressure roller gap is manually adjusted, the sign shows that the adjustment range is 4- 12mm.

◆ Rubber mixing ink system. Steel pipe surface coated with wear-resistant rubber, medium and high special grinding. Gap electric adjustment, digital display, adjustment range 0- 6mm. (Optional: scraper ink leveling system)

◆ Grinding roller: idling device with separate motor drive to ensure that the ink does not dry when shut down. Network cable: 160-500 Optional. (Optional: Ceramic mesh collection)

◆ The drawing ring can be quickly moved and locked. (Optional: full vacuum transmission system)

Slot unit

◆ Prepress wheel device: electric linkage slotting, wire pressing, prepress once completed.

◆ Electric adjustment of the length, width, height and folding part of the carton, digital display.

◆ The gap of the wire wheel is adjusted manually, and the dial shows the adjustment value .

◆ Slotting knife thickness 7mm, alloy steel material, serrated heat treatment tooth grinding, sharp blade, high precision.

◆ The slot phase is adjusted by computer electric numerical 360 degree.

◆ Add hand hole die holder.

◆ The slotting part is equipped with interlocking control switch to realize emergency stop, stop or resume paper feeding.

Die cutting unit

◆ Manual adjustment of die cutting pressure gap.

◆ Rubber cushion roller automatic transverse moving device.

◆ Imported quick- change rubber pad, abrasion resistance.

◆ Speed difference compensation system to ensure the consistency of line speed and ensure accuracy.

◆ Rubber pad grinding mechanism, prolong the service life of rubber pad, reduce consumption.

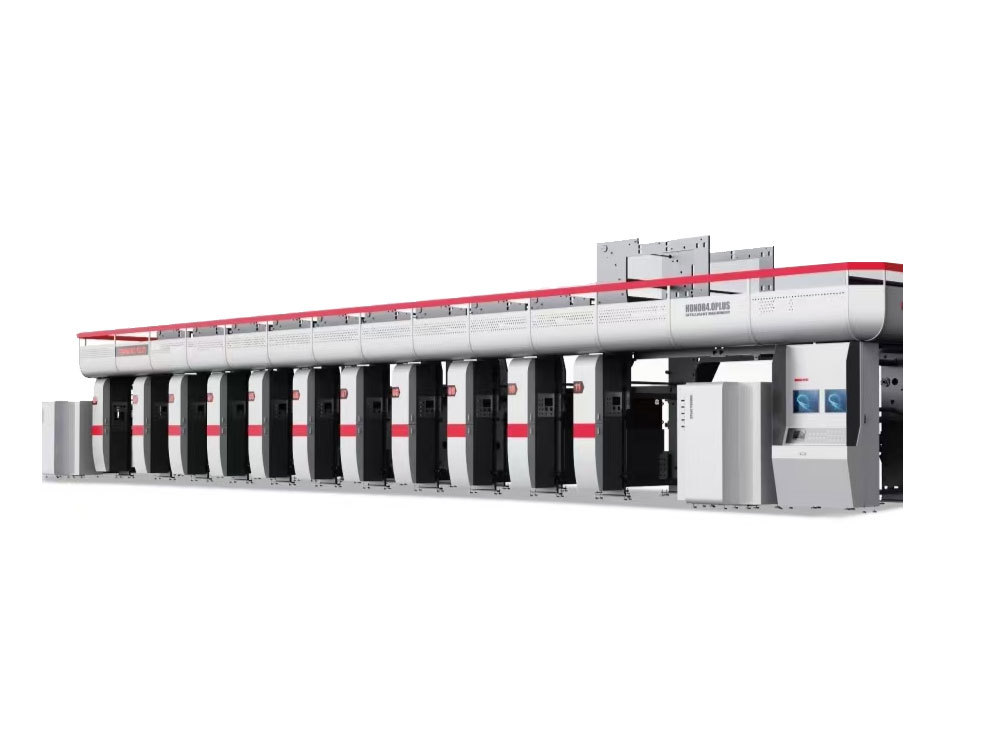

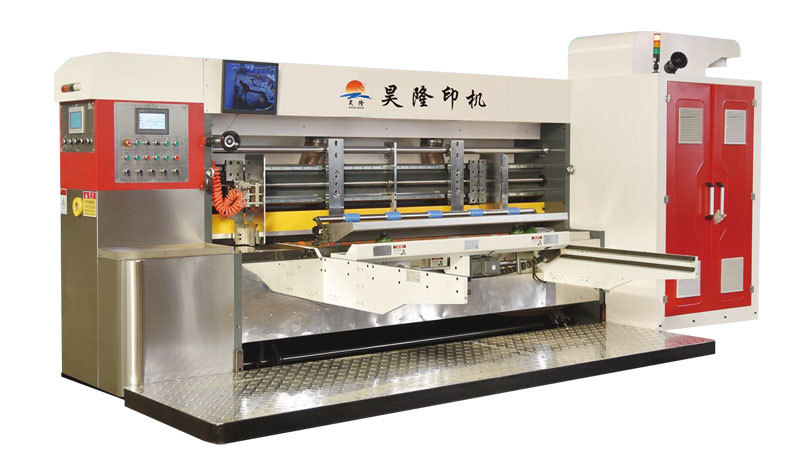

The Full computer high speed ink printing slotting die cutting machine is a remarkable piece of equipment. It combines cutting-edge technology with high efficiency and precision. This machine is capable of rapid and accurate ink printing, ensuring vibrant and clear patterns on various materials. The slotting and die cutting functions are seamlessly integrated, allowing for complex shapes and designs to be achieved with ease. Its fully computerized control system enables smooth operation and easy adjustment, meeting the diverse needs of different production runs. With its advanced features and reliable performance, it is an essential tool for the packaging and printing industry, bringing high-quality output and enhanced productivity.

Company Profile

Haolong Machinery is located in the carton machinery industrial park of Dongguang County, Cangzhou City, within the Bohai Economic Cooperation Zone. It is close to the Beijing-Shanghai Railway and the Beijing-Fuzhou Highway, with superior geographical conditions and convenient transportation.

Haolong Machinery is a manufacturer specializing in semi-automatic carton stapling machines. While drawing on advanced technologies and experiences from domestic and international products, we strictly control product quality, continuously improve and innovate, making the operation of the entire machine more convenient and efficient. This effectively enhances the working efficiency of the machines and extends their service life, meeting market demands. We prioritize customer interests and adhere to the principles of "emphasizing quality, service, reputation, and contracts, with a people-oriented and customer-first approach," which has earned us unanimous praise from domestic and international customers. We welcome new and old customers to visit, inspect, and place orders.

Production Site

Customer Group Photo

Factory Video

TAG:

Full computer high speed ink printing slotting die cutting machine

Category: