Application and characteristics

◆ The main electrical appliances of the whole machine are made of French Schneider products.

◆ Adopt leading edge paper feeding system.

◆ Adopt bevel gear drive, gear by high- -frequency quenching, grinding teeth.

◆ AlI rollers are chrome plated to enhance hardness.

◆ Gear adopts spray type circulation lubrication.

◆ PLC, touch screen multi-function control, inverter controller, accurate and reliable.

◆ Automatic zero, automatic version.

◆ Module design, multi-color printing unit arbitrary combination.

◆The side baffle and grooving parts of the paper feeding part are electrically adjusted.

◆ Tool roll, soft roll adopts international standard size, strong versatility, anywhere can buy the appropriate template and rubber pad.

◆ With the speed difference compensation device, automatically track the speed of the compensation rubber pad roller, to ensure that the size of the carton and the cutter die are completely consistent.

Technological parameter

| Type | ZYKM-1022 | ZYKM-1224 | ZYKM-1228 | ZYKM-1424 | ZYKM-1428 | ZYKM-1624 | ZYKM-1628 | ZYKM-1632 | |

| Max. speed(piece/min) | 150 | 150 | 140 | 150 | 140 | 120 | 120 | 100 | |

| Paper feeding precision(mm ) | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | |

| Max. feed size(mm) | 1000×2300 | 1200×2500 | 1200×2900 | 1400×2500 | 1400×2900 | 1600×2500 | 1600×2900 | 1600×3300 | |

| Min. feed size(mm) | 300×600 | 350×600 | 350×600 | 400×600 | 400×600 | 450×600 | 450×600 | 450×600 | |

| Size of drawing paper(mm) | 1300×2100 | 1500×2500 | 1500×2900 | 1700×2500 | 1700×2900 | 2000×2500 | 2000×2900 | 2000×3300 | |

| Max. printing area(mm) | 1000×2200 | 1200×2400 | 1200×2800 | 1400×2400 | 1400×2800 | 1600×2400 | 1600×2800 | 1600×3200 | |

| Printing set(mm) | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | |

| Thickness of standard printing plate (mm) | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | |

| Min. slotting interval (mm) | Positive knife | 160×160 | 160×160 | 160×160 | 160×160 | 160×160 | 160×160 | 160×160 | 180×180 |

| Scalpel | 270×65 | 270×65 | 270×65 | 270×65 | 270×65 | 270×65 | 270×65 | 290×70 | |

| Max. groove depth(mm) | 250 | 300 | 300 | 350 | 350 | 400 | 400 | 400 | |

| Slotting accuracy (mm) | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | |

| Die cutting precision (mm) | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | |

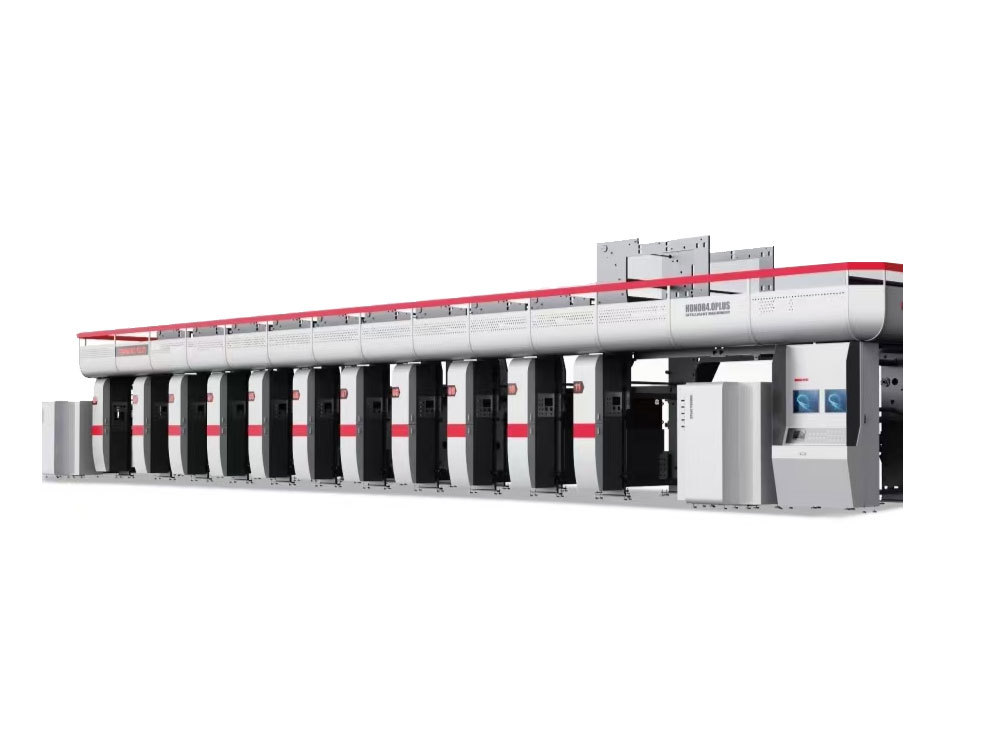

High speed ink printing slotting die cutting machine is a remarkable piece of equipment. It combines precision, efficiency, and advanced technology. This machine is capable of rapid and accurate ink printing, ensuring vibrant and clear prints on various materials. The slotting and die cutting functions are seamlessly integrated, allowing for precise shaping and cutting of the printed products. With its high speed operation, it significantly boosts productivity in the production process. It is designed to handle large volumes of work with ease, delivering consistent and high-quality results. Its user-friendly interface and reliable performance make it an ideal choice for industries that demand excellence in printing and converting. Whether for packaging, cardboard, or other materials, this machine is a game-changer, offering superior quality and efficiency in one compact unit.

Company Profile

Haolong Machinery is located in the carton machinery industrial park of Dongguang County, Cangzhou City, within the Bohai Economic Cooperation Zone. It is close to the Beijing-Shanghai Railway and the Beijing-Fuzhou Highway, with superior geographical conditions and convenient transportation.

Haolong Machinery is a manufacturer specializing in semi-automatic carton stapling machines. While drawing on advanced technologies and experiences from domestic and international products, we strictly control product quality, continuously improve and innovate, making the operation of the entire machine more convenient and efficient. This effectively enhances the working efficiency of the machines and extends their service life, meeting market demands. We prioritize customer interests and adhere to the principles of "emphasizing quality, service, reputation, and contracts, with a people-oriented and customer-first approach," which has earned us unanimous praise from domestic and international customers. We welcome new and old customers to visit, inspect, and place orders.

Production Site

Customer Group Photo

Factory Video

TAG:

High speed ink printing slotting die cutting machine

Category: