Application and characteristics

◆ Easy operation, only need move your fingers on the touch screen.

◆ Operator no need experience, to make the manufacturer more resilient to arrange the production.

◆ Fast speed, Stitching speed: 600 stitch/min.

◆ Efficient production, middle sized carton box, one hour can finish stitching more than 2000.

◆ High flexibility, can single stitching, double stitching ,reinforce stitching, can be suitable for different companies' requires for stitching types. Change single stitching, double stitching, reinforce stitching, only need click on the touch screen.

◆ Different carton size changing, only need 1-2 minutes.

◆ Stitching distance no error, beautiful,adjustable 20-120mm.

◆ Auto counting, statistical quantity, and can set separation go out, cooperate the back tinishing machine works.

◆ The automatic wire feeding function ensures that the wire feeding is correct, and the use of large flat wire can save wire changing time.

Main spare parts

◆ Japanese Yaskawa servo motor

◆ Japanese Omron PLC

◆ Taiwan SHIHLIN contactor

◆ France Schneider relay

◆ Taiwan willenton touch screen

◆ Japanese SHIMPO stitching head reducer

◆ Taiwan AIRTAC cylinder Solenoid valve

◆ Guangdong(Dongguan) stitching head

◆ Foshan Yuanmingchuang synchronous belt wheel

◆ Taiwan Aimoxin gear reduction motor

Technological parameter

| Max. paper size (A+B) *2 (mm) | 3600mm |

| Min. paper size (A+B) *2 (mm) | 700mm |

| Max.cover C (mm) | 350mm |

| Min.Cover C (mm) | 65mm |

| Max width (C+D+C) (mm) | 350mm |

| Max carton width ( mm) | 700mm |

| Min.carton width (mm) | 1 50mm |

| Max. carton length (mm) | 1100mm |

| Man. Carton length (mm) | 1 50mm |

| Machine power (KW) | 4kw |

| Machine dimension ( mm) | 2800x2600mm |

| Machine weight(KG) | 1500Kg |

| Nail distance(smal/big) (mm) | 20-1 20mm |

| Machine speed nail/min | 600 nails/min |

| Wire No. | 17, 18 |

| Nail No. | 1-99 |

Processing diagram

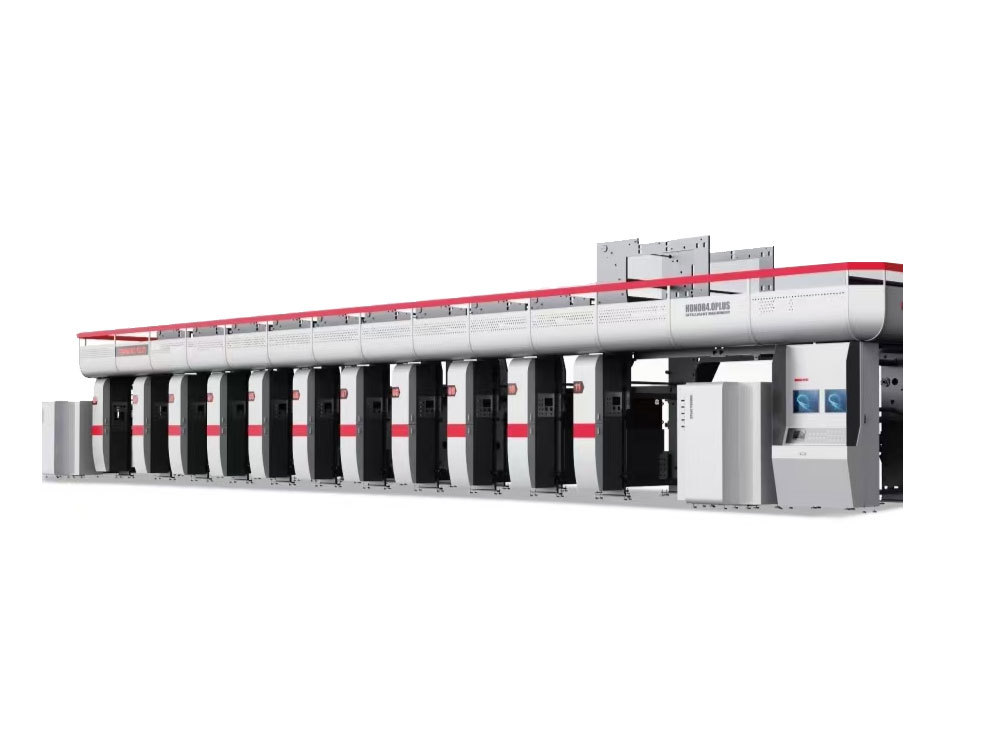

The Double servo control single-piece stitching machine is a cutting-edge piece of equipment. It features precise double servo control that ensures accurate and consistent stitching. This machine is designed to handle single-piece stitching with high efficiency and quality. The advanced servo technology allows for smooth operation and quick response, minimizing errors and enhancing productivity. It can adapt to various stitching requirements, providing flexibility in different manufacturing scenarios. With its reliable performance and user-friendly design, it is an ideal choice for industries that demand superior stitching results, making the stitching process effortless and efficient.

Company Profile

Haolong Machinery is located in the carton machinery industrial park of Dongguang County, Cangzhou City, within the Bohai Economic Cooperation Zone. It is close to the Beijing-Shanghai Railway and the Beijing-Fuzhou Highway, with superior geographical conditions and convenient transportation.

Haolong Machinery is a manufacturer specializing in semi-automatic carton stapling machines. While drawing on advanced technologies and experiences from domestic and international products, we strictly control product quality, continuously improve and innovate, making the operation of the entire machine more convenient and efficient. This effectively enhances the working efficiency of the machines and extends their service life, meeting market demands. We prioritize customer interests and adhere to the principles of "emphasizing quality, service, reputation, and contracts, with a people-oriented and customer-first approach," which has earned us unanimous praise from domestic and international customers. We welcome new and old customers to visit, inspect, and place orders.

Production Site

Customer Group Photo

Factory Video

TAG:

Double servo control single-piece stitching machine(Automatic wire feeding)

Category: